We were invited by Cherry Mobile to visit the 2 factories that supply components and devices for them. It was a surreal experience because we got the chance to see how the key components of a mobille are made, assembled and packed for Cherry Mobile.

Cherry Mobile is actually the first local mobile phone company that is brave enough to willingly share this experience to all of us; and we find it as a great display of transparency and trust.

The experience we had hit 2 birds with 1 stone: (1) their spirit of openness make us love the brand more, and; (2) it gave them the opportunity to show that the products they market and sell to Filipinos are made with utmost consideration to quality, and encourage Filipinos to avoid buying counterfeit ones. This brave move by Cherry Mobile isn’t just beneficial to their brand, but also to other brands or their competitors as well like Samsung, Starmobile, MyPhone, OPPO, etc.

Quin An Electronics, Shenzhen

Quin An is Cherry Mobile’s supplier of battery charger and some of their accessories. Quin An is an ISO 9000 quality management system holder. It houses several assembly lines specifically for battery chargers. I personally didn’t know that making and assembling a charger is a little more complicated than I imagined.

ISO 9000 is a quality management standard that presents guidelines intended to increase business efficiency and customer satisfaction. The goal of ISO 9000 is to embed a quality management system within an organization, increasing productivity, reducing unnecessary costs, and ensuring quality of processes and products.

www.pjr.com/standards/iso-90012008/benefits-of-iso–9000

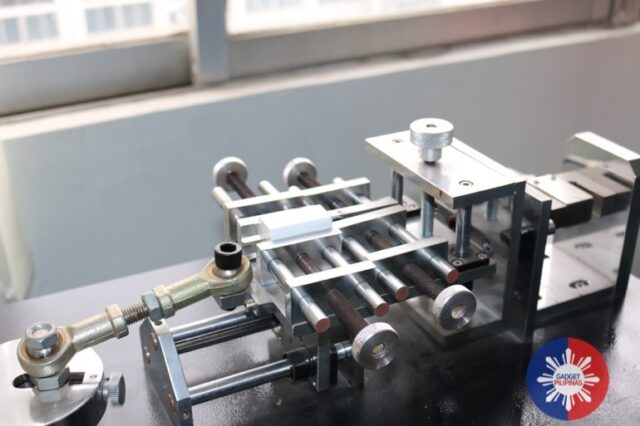

Quin An is also the hub of several charger testing facilities. In fact, there’s one room inside the building solely for testing equipment. Check out some of the photos we took inside the testing room.

Plug Testing Machine at Quin An, Shenzhen

Interestingly, Quin An also supplies components and an OEM of the following brands/products:

- Jiayu/Cherry Mobile*: components/Mobile Phone Assembly

- Foxconn: Media Speaker/Cable Assembly

- Lenovo: Cell Phone Speaker/Earphone/Cable Assembly

- Haier: Cell Phone Earphone

- LiteOn: Cell Phone Speaker/Earphone

- Audio-Technica: Earphone

[su_permalink id=”https://www.unbox.ph/gadget/cherry-mobile-buys-controlling-stake-in-jiayu-will-release-pinoy-designed-smartphone/” target=”blank”]Check out related article by Unbox: Cherry Mobile Buys Controlling Stake In Jiayu, Will Release Pinoy-designed Smartphone[/su_permalink]

According to Quin An, they are capable of manufacturing 100,000 pieces of earphones daily; 100,000 pieces of data cables daily, and; 6,000 pieces of consumer electronics daily. Be sure to check out the video above to see how they manufacture battery chargers. You may also click this link to watch the video directly on YouTube.

After visiting Quin An, we headed to Dongguan, China to visit CKY. CKY manufactures mobile phone batteries for Cherry Mobile. Surprisingly, CKY also assembles one of the well-known products of Cherry Mobile, the Cherry Mobile Flare X.

Apart from the Cherry Mobile Flare X assembly line, what really piqued our interest are how they manufacture the batteries, and how each battery is subjected to rigid quality testing. We were given exclusive look at their battery assembly lines, and were utterly amazed on CKY’s system and operations.

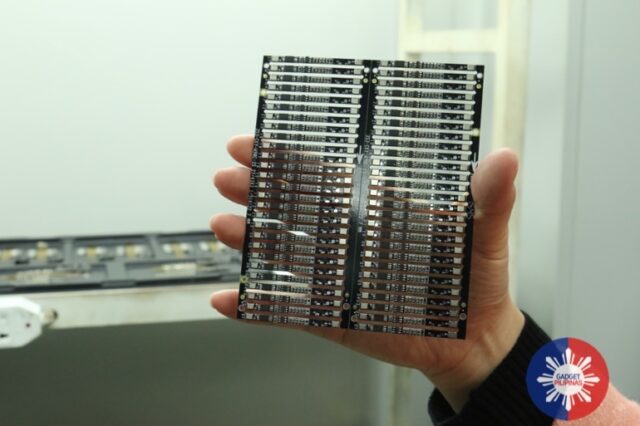

We were also informed that CKY installs 8-pin PCB boards on their batteries. According to them, this type of board is much safer than conventional 6-pin PCB board. In addition to using such type of board, CKY also puts a layer between the PCB boards and the Lithium Ion battery poles. Some fake and counterfeit batteries you can purchase (at Quiapo for instance) have very thin or no layer, which may be very risky for consumers. Our video below shows the effect of having no layer between the board and the battery.

The original Cherry Mobile battery (left) and fake Cherry Mobile battery (right) were both subjected to puncture test.

Click this YouTube video link to see the actual battery puncture test we experience during our trip over the weekend.

While we all marvel at CKY’s and Quin An’s processes, and the quality of products they produce, there’s still one facet that all brands – not just Cherry Mobile – must always do well and consider: after-sales. Cherry Mobile has been at the top of its game ever since the 1st Flare came out. Unfortunately, they – along with other local brands – have been a subject of flak by some consumers because of (apparently) slow after-sales service and lack of spare parts. All brands – local or international – must consider that with great volume of sales comes great demand on customer service.

We will be posting more contents about our recent trip to China, and I hope that you’ll follow us and our contents.

[su_spoiler title=”Disclosure” open=”yes” style=”fancy” icon=”plus-square-1″]Our trip to China was paid for by Cherry Mobile. The purpose of this content is to show everyone the importance of purchasing original accessories and components regardless of brand you’re patronizing. There is a plethora of counterfeit products out in the market, and everyone must stay vigilant and careful when procuring items. Buy original. Stay safe.[/su_spoiler]

Giancarlo Viterbo is a Filipino Technology Journalist, blogger and Editor of gadgetpilipinas.net, He is also a Geek, Dad and a Husband. He knows a lot about washing the dishes, doing some errands and following instructions from his boss on his day job. Follow him on twitter: @gianviterbo and @gadgetpilipinas.